Rubber Processing Performance and Physical-Mechanical Property Testing Equipment

The adaptability of rubber compounds to processing machinery during mixing, extrusion, molding, or vulcanization is referred to as “processability.” A thorough understanding of a compound’s processability helps prevent labor and energy waste, equipment overload, and allows unsuitable raw materials to be repurposed while improving product uniformity.

The physical-mechanical properties of vulcanized rubber compounds are critical factors determining product performance. Basic physical property tests include measurements of elasticity, hardness, density, mechanical properties, and flex fatigue resistance.

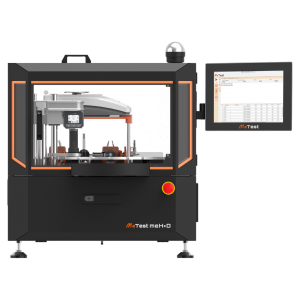

Characterization of Rubber Compound Rheological Properties

The rheological properties of a rubber compound refer to the relationship between its viscosity, elasticity, temperature, and shear rate. These properties serve as indicators of the rubber’s behavior or phenomena during vulcanization, holding significant practical value for scientific research and production guidance. Among various methods for measuring rubber vulcanization characteristics, the curemeter is considered the most effective.

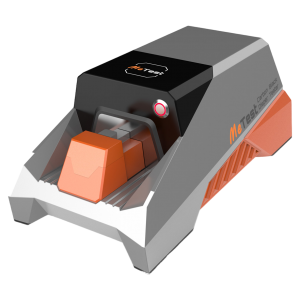

Determination of Carbon Black Dispersion in Rubber Compounds

Filler dispersion is a critical parameter in the rubber products and tire industry, as it directly influences product performance and has become an essential quality control metric. When fillers are uniformly dispersed in a rubber compound, the freshly cut surface reflects light as a smooth, even, and flawless plane. Conversely, poor filler dispersion results in surfaces exhibiting ring-shaped or convex “lumps” or concave pockmarks. The MonTech carbon black dispersion analyzer enables rapid and accurate determination of dispersion grades.

Carbon Black Dispersion Analyzer

Flex Cracking Test

Many rubber products (such as tires, conveyor belts, rubber supports, rubber bearings, V-belts, etc.) are subjected to cyclic stress during use. Under the influence of periodic stress, changes in the structure and properties of rubber occur, a phenomenon known as flex fatigue.

Basic Physical Property Testing

High elasticity is a valuable property of rubber; hardness indicates its ability to resist indentation and deformation. The hardness of vulcanized rubber can be used to assess the quality of compound mixing and the degree of vulcanization in semi-finished products. Density determines the mass of rubber required to fill a given mold cavity, which is crucial for calculating product costs.

Mechanical Property Testing

Any rubber product is designed to function under specific external force conditions, necessitating certain physical and mechanical properties. These include tensile properties, tear resistance, and other related characteristics.