meLFTD De Mattia Flexing Fatigue Tester

This equipment is capable of simultaneously performing material flexural testing, crack propagation testing, and tensile fatigue testing. It complies with the testing requirements of ISO 132, ISO 6943, ASTM D 430-B, D 813, and DIN 53 522 -1/2/3. Designed for long-term continuous operation, it serves both quality control in rubber manufacturing processes and R&D applications such as formulation development.

Equipped with a high-precision linear motor (non-traditional eccentric-wheel structure) and an optional CCD imaging system, the device offers user-friendly operation and enhanced adaptability to customer testing needs. Additionally, it integrates needs**. Additionally, it integrates a custom temperature control chamber from Binder GmbH (Germany), ensuring high-precision and stable thermal regulation.

Features and Advantages

- Industrial design with aesthetically pleasing appearance and low operational noise.

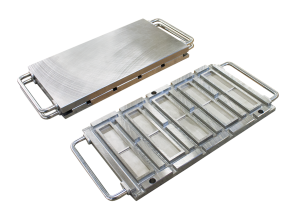

- Ultra-rigid mold cavity designed using finite element analysis, ensuring durability and robustness.

- Equipped with a high-precision linear motor (non-traditional eccentric wheel structure).

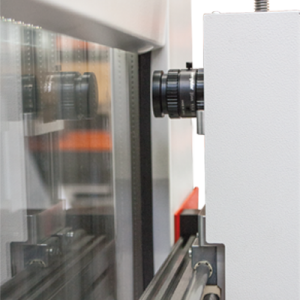

- Optional CCD system for enhanced testing accuracy.

- User-friendly software interface with guided operation and integrated automatic calibration module.

- Test data can be uploaded to LIMS or MES.

- Transparent protective cover provides clear visibility and a safe testing environment.

- Emergency stop button and misuse protection ensure operational safety.

- Integrated self-diagnostic routines alert operators to system or operational faults.

De Mattia Flexible Mold (5-cavity)

De Mattia Flexible Mold (5-cavity)