Rubber Vibration Damping Component Performance Testing

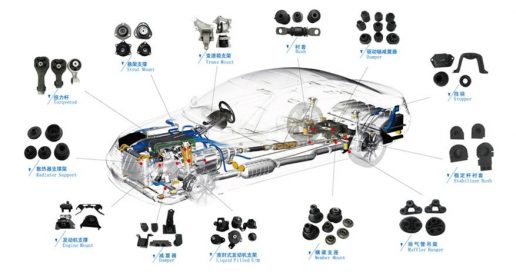

The primary function of shock absorbers is to accelerate the attenuation of frame vibrations, thereby improving ride comfort in mechanical systems. In modern vehicles, shock absorbers are typically integrated into the suspension system, ensuring both safety and operational stability.

Importance of Rubber Shock Absorbers:

Rubber, as a material, exhibits high elasticity and viscoelasticity, making it an excellent medium for vibration damping and noise reduction. Compared to rigid materials, rubber is lighter in weight and capable of significant elastic deformation. Its inherent properties enable it to withstand substantial impact forces, thereby reducing deformation in mechanical components caused by shocks. The flexible nature of rubber allows for greater design freedom in shaping shock absorbers, while the hardness of the components can be precisely adjusted through engineering design to better meet the specific requirements of mechanical systems.

Application of Damping Components in Automobiles

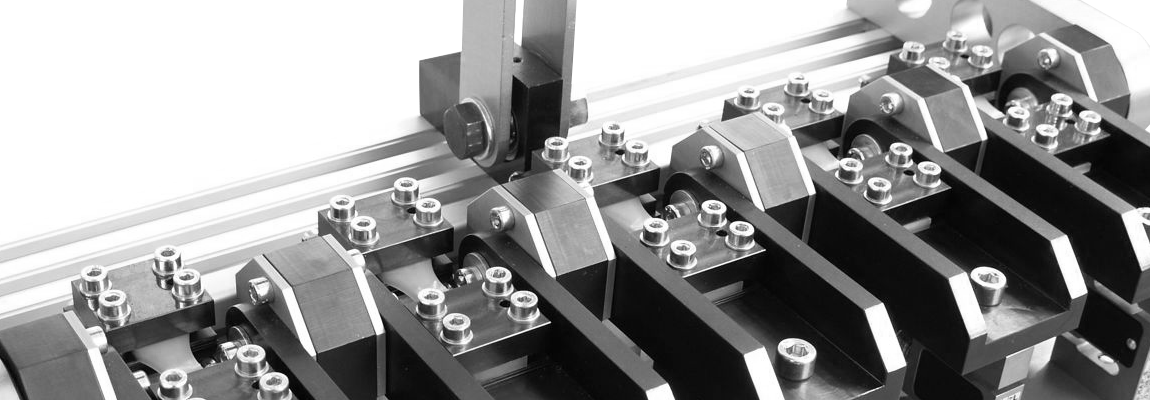

Rubber Sample Preparation and Performance Testing Equipment

Our testing system encompasses a comprehensive range of instruments, software solutions, and after-sales services for rubber and elastomer testing, addressing diverse requirements including static tests, dynamic rheological analysis, viscosity measurement, processability evaluation, mechanical-physical property assessment, and sample preparation.

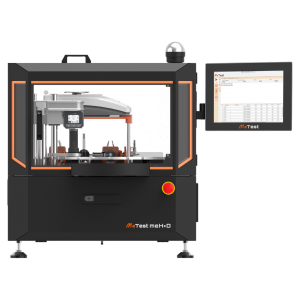

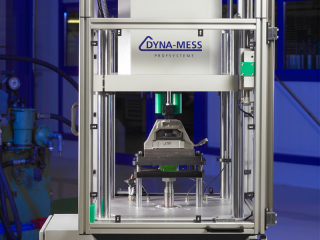

Dynamic Testing Machine

We offer a wide range of standard dynamic testing machines with flexible designs to meet diverse testing requirements, while also developing customized specialized testing instruments based on client needs.

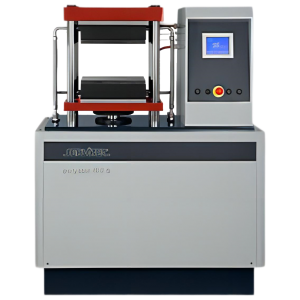

Static Universal Material Testing Machine

TO Universal Material Testing Machine integrates sophisticated design, high-quality standards, and advanced technological engineering into a high-precision instrument.